Bending & Shaping

At Bowstone, we specialize in minimizing waste and achieving precise angles in metal bending and shaping. Our advanced equipment and software streamline processes for efficient order fulfillment. Contact us today to learn more about our bending and shaping services. We offer many metal shaping services, including:

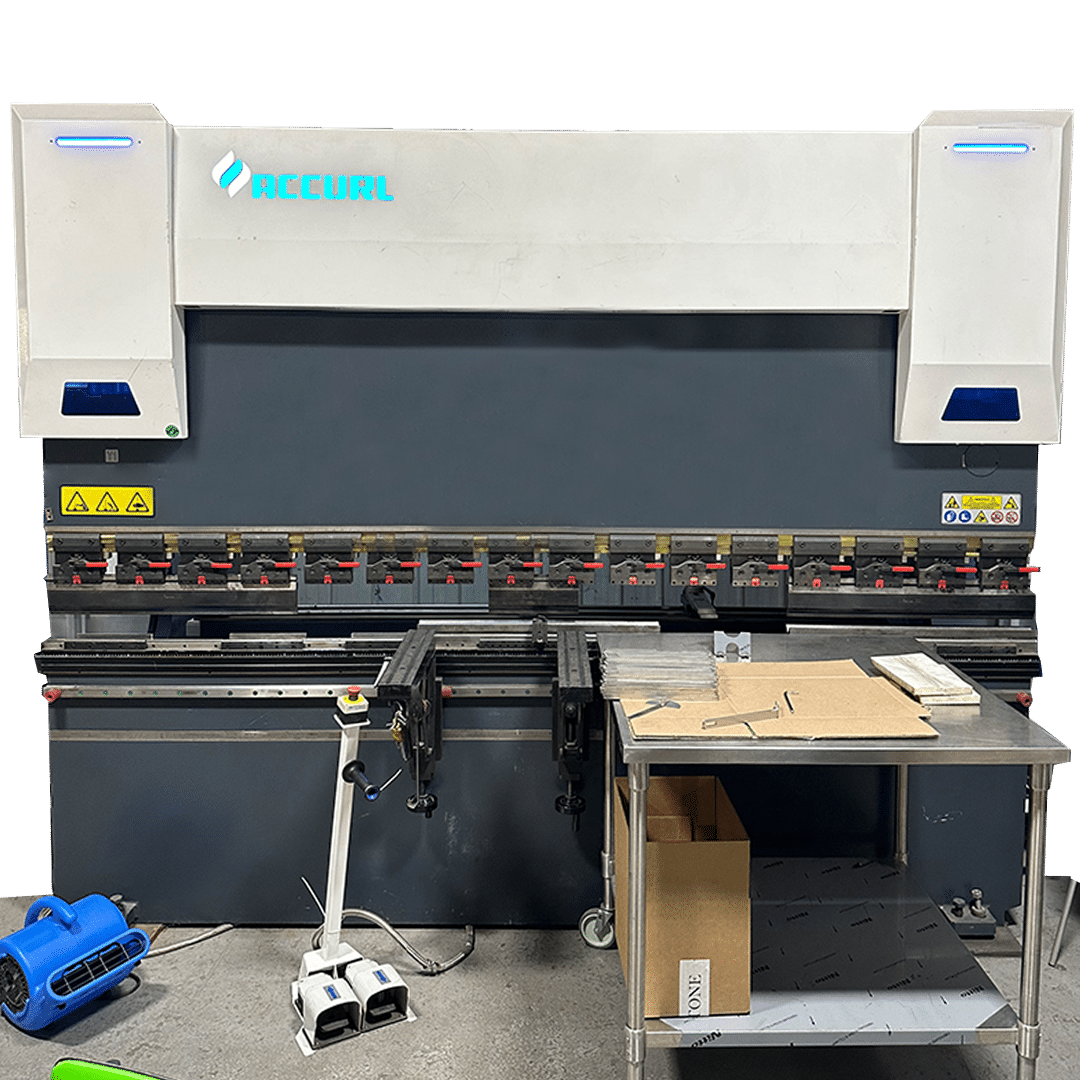

At Bowstone, our robust equipment allows for metal bending up to 12 feet in length.

Our team’s versatility with the tools at Bowstone allows for unlimited shape options & variations. There are a number of different methods that BowStone uses for metal bending and shaping, including stamping, die-cutting, hydroforming, and press brake forming.

Metal Fabrication Services Based In Georgia

Driving Results with Expert Solutions

Bowstone has been providing quality bending and shaping services to our customers internationally and nationally. We offer a wide range of services, from simple repairs and fabrication projects all the way up to complex manufacturing jobs with unique specifications that require specialized equipment. Our team of experts has the skills and experience necessary to get the job done right, on time, and within budget. No project is too big or too small for our team – we’re here to help you with all of your fabrication needs!

Testimonials

What Our Clients Say About Us

“Bowstone goes above and beyond on every order they receive from my company. Their eye for detail is second to none. Their quality of product is beyond any norm set in the industry today. Their people treat you like family. Ownership is committed to ultimate excellence and performs flawlessly everyday. I am glad to count them as friends.”

Wayne V.

“We’ve worked with Bowstone for years. They are an excellent supplier and are continually expanding their capabilities. They usually beat the competition on most price quotes and are able to provide good lead times.“

Jason M.

“Called with an emergency hitch project. Sent a quick drawing with a few measurements and pictures of others that we’ve had built in the past. Completed in one day!! Good price and done.. Hard to find that anymore, will use again when the time arises.. Thank you”

Sean H.