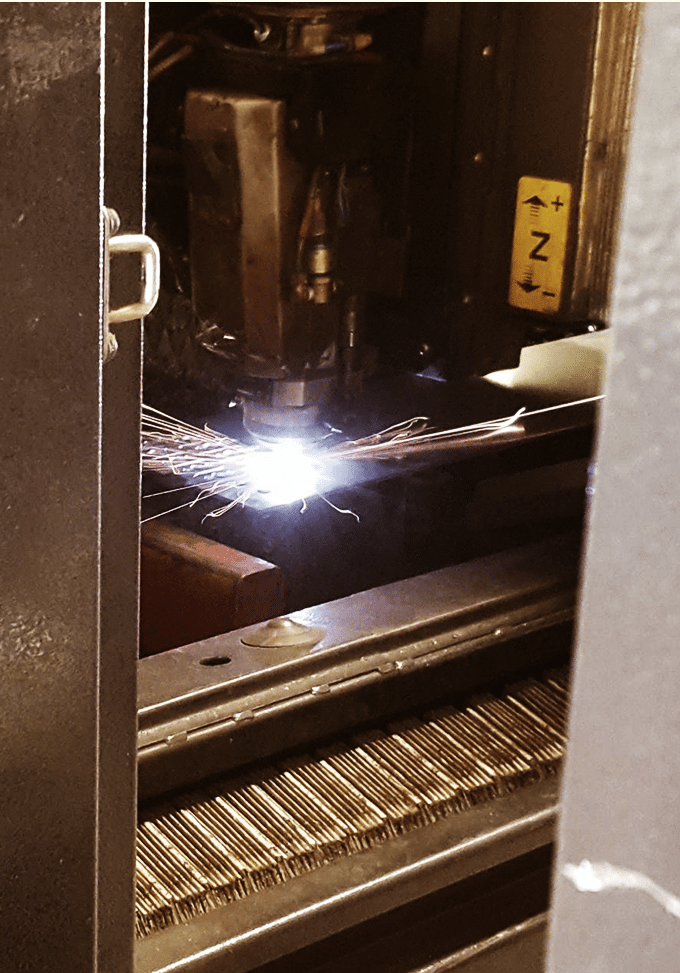

Laser Cutting Capabilities

Bowstone utilizes laser cutting to offer intricate designs and tight tolerances on industrial metal fabrication projects. This method is ideal for cutting sheet metal including 1.5 inch CR steel and 1 inch Stainless Steel, reducing material deformation and giving a cleaner edge finish.

Laser Cutting Process

Laser cutting is a popular manufacturing process that uses a laser to cut materials. The laser-cutting process is exact and can create intricate designs and patterns along with our bending and shaping process. Laser cutting is often used in producing electronics, medical devices, and automotive parts. Bowstone utilizes the Mazak Optiplex Nexus Fiber S7 to cut 1.5-inch CR steel and 1-inch Stainless Steel. The system boasts incredible precision and readability, control, and integrity, similar to CNC precision.

Jet cutting is a type of machining that uses high-pressure water jet to cut through the material. The jet of fluid acts like a mini saw blade, slicing through the material with precision and without leaving any burrs or rough edges. Water-Jet cutting is often used for delicate materials or in situations where traditional cutting methods would damage the material. At Bowstone, we can cut a 2ft depth of any material (glass, metal, stone, composite) with micro precision. Water Jet creates the best satin-smooth edge, without heat-affected zones and mechanical stress.

Need laser or jet-cutting services? Schedule a consultation with the team at Bowstone and find out how we can help get the job done.

Metal Fabrication Services Based In Georgia

Driving Results with Expert Solutions

Bowstone has been providing quality bending and shaping services to our customers internationally and nationally. We offer a wide range of services, from simple repairs and fabrication projects all the way up to complex manufacturing jobs with unique specifications that require specialized equipment. Our team of experts has the skills and experience necessary to get the job done right, on time, and within budget. No project is too big or too small for our team – we’re here to help you with all of your fabrication needs!